With all the different tasks wall ties must perform and all the related regulations for their use, it’s no wonder the question ‘which wall tie do I use?’ is one we hear all the time. As the UK’s leading independent wall tie manufacturer, we are in a strong position to give you the correct advice.

It’s a complex area, so this blog won’t be covering every last detail of every wall tie we make. It’s simply intended to give you a sound overview of what can be used, where and why. If you would like further advice, our technical teams are always willing to answer any questions.

These ties act to secure two leaves of a cavity wall to each other, allowing them to act as one structurally. A cavity tie usually incorporates some mechanism, (usually a change of shape) to discourage moisture moving across the tie. Most cavity ties are available with a dedicated clip to secure insulation (usually in sheet form) within the cavity. There are 4 standard classifications (Types) of masonry to masonry wall ties:

These ties act to secure two leaves of a cavity wall to each other, allowing them to act as one structurally. A cavity tie usually incorporates some mechanism, (usually a change of shape) to discourage moisture moving across the tie. Most cavity ties are available with a dedicated clip to secure insulation (usually in sheet form) within the cavity. There are 4 standard classifications (Types) of masonry to masonry wall ties:

Type 1 – Heavy Duty Wall Tie

A heavy-duty wall tie suitable for most building sizes and types. These ties are rigid and should not be specified where large differential movements are expected or low strength masonry units are in use. They are suitable for buildings of any height and most UK locations. BPC Type 1 wall ties include the VST1, VE1, VS6 and the Neutras 1.

Type 2 – General Purpose Wall Tie

A general-purpose wall tie for applications such as small commercial buildings and domestic properties. They are suitable for buildings with a maximum height if 15m and for flat sites where the basic wind speed is up to 31m/s and altitude is not greater than 150m above sea level. When you’re ordering Type 2 ties, ask for EN2, VE2, V26 Neutras 2 or TPT.

Type 3 – General Purpose Wall Tie

As Type 2 above but where the basic wind speed does not exceed 27m/s. For a Type 3 tie ask for the V26 300mm long.

Type 4 – Light Duty Wall Tie

A light duty wall tie used in box-form domestic dwellings that have inner and outer leaves of a similar thickness. They are suitable for buildings with a maximum height if 10m and for flat sites where the basic wind speed is up to 27m/s and altitude is not greater than 150m above sea level. The VE4 light duty housing tie is our standard Type 4 tie and the Neutras range are low thermal conductivity wall ties.

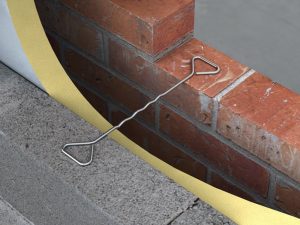

This type of wall tie is specifically designed to secure an inner timber frame to an outer brick skin. The main property of these ties is that they can absorb substantial vertical movement between the brick and timber, whilst still performing their structural function.

This type of wall tie is specifically designed to secure an inner timber frame to an outer brick skin. The main property of these ties is that they can absorb substantial vertical movement between the brick and timber, whilst still performing their structural function.

Type 5 – Timber Frame Ties

These are timber frame ties suitable for domestic houses and industrial/commercial developments of up to three storeys. They are suitable for buildings with a maximum height of 15m on flat sites where the basic wind speed is up to 25m/s and the altitude is not greater than 150m above sea level.

Type 6 – Timber Frame Ties

This type of timber frame wall tie is right for domestic and small commercial builds up to four storeys high. They are suitable for buildings with a maximum height of 15m and for flat sites where the basic wind speed is up to 25m/s and altitude is not greater than 150m above sea level. Our V61 Timber Frame Tie or Helical Timber Frame Wall Ties are the ideal choice here.

Type 7 – Timber Frame Ties

Similar to Type 6 ties but intended for use in taller buildings from five up to seven storeys high. Their suitability should be calculated for each location and the Vista technical team are more than happy to assist.

These ties allow masonry walls to be tied back to other structures, (steelwork or masonry) providing restraint in one direction but allowing movement in the other. This is achieved by placing a debonding sleeve over the part of the tie which is to be embedded in the wall, allowing the tie to move within the sleeve. Safety Plain End Ties are used in movement joints where they occur in long runs of brickwork, the ties spanning over a vertical joint preventing vertical movement but allowing horizontal expansion and contraction.

These ties allow masonry walls to be tied back to other structures, (steelwork or masonry) providing restraint in one direction but allowing movement in the other. This is achieved by placing a debonding sleeve over the part of the tie which is to be embedded in the wall, allowing the tie to move within the sleeve. Safety Plain End Ties are used in movement joints where they occur in long runs of brickwork, the ties spanning over a vertical joint preventing vertical movement but allowing horizontal expansion and contraction.

BPC products include the Safety Plain End Tie, Plain End Frame Cramp, Dovetail Plain End Tie the Plain End Clasp.

These products allow masonry walls to be restrained back to other elements of the structure. This could be pre-exis ting walls, or new or pre-existing steel work. The ties, once in position prevent sideways movement between a wall and another structure.

ting walls, or new or pre-existing steel work. The ties, once in position prevent sideways movement between a wall and another structure.

BPC products include the Frame Cramp, Frame Cramp with Drip, Slotted Frame Cramp, Slotted Frame Cramp with Drip, Wire Frame Cramp, Wire Clasp Tie, Clasp Tie, Column Tie and the Offset Frame Cramp

These products allow vertical movement whilst offering horizontal restraint. The channel system tends to be face-fixed whilst the slot is usually cast into concrete. These systems may be used to overcome differences in coursing between masonry leaves.

These products allow vertical movement whilst offering horizontal restraint. The channel system tends to be face-fixed whilst the slot is usually cast into concrete. These systems may be used to overcome differences in coursing between masonry leaves.

BPC Chanel Systems include the Steel Frame Channel, Dovetail Slot, 28/15 Plain Back Channel, 28/15 Slotted Back Channel and the 28/15 Tangled back Channel. Once fixed these channels are used with a choice of the Dovetail Safety Tie, Dovetail Safety Tie with Drip, Dovetail Wire Tie or the Steel Channel Tie. For the correct combination for your project please contact the technical team.

These type of systems secure cavity walls to overhead structures, whilst accommodating vertical movement and are used in conjunction with one way sliding ties or two way sliding ties.

These type of systems secure cavity walls to overhead structures, whilst accommodating vertical movement and are used in conjunction with one way sliding ties or two way sliding ties.

BPC sliding anchor systems include the Welded A Stem, Welded B Stem, Welded E Stem, Bent C Stem, Twisted D Stem and the Twisted F Stem

These products are used in existing cavity walls where wall ties have been omitted or have corroded. The BPC range of remedial ties includes the Wavy Tail Tie, the Cavity Starter Tie, the Remedial Helical Ties and the Mechanical Remedial Ties.

These products are used in existing cavity walls where wall ties have been omitted or have corroded. The BPC range of remedial ties includes the Wavy Tail Tie, the Cavity Starter Tie, the Remedial Helical Ties and the Mechanical Remedial Ties.

Starter Ties allow new walls to be joined to existing structures. They can be used to extend an existing structure or they can be used to help create an additional leaf where a cavity is required, for example in the restoration or conversion of an old building. At BPC we offer four options, the Universal Stainless Steel Wall Starter System, the Starter Tie, the Starter Frame Tie and the Cavity Starter Tie.

There is a range of British Standards that affect the design and use of wall ties. Overall the idea is to provide a minimum standard for all wall tie manufacturers and builders to adhere to.

For our part at BPC Fixings, we’ve always sought to provide more than the minimum standard.

Eurocode 6 – Code for the Design of Masonry structures (BS EN 1996-1-1:2005). This refers to BS EN 845-1 for wall tie usage. (See below)

BS EN 845-1:2013+A1:2016 – Specification for ancillary components for masonry

This specifies the standard requirements for wall ties, including materials, tolerances, testing and declared values.

PD 6697:2019 Recommendations for the design of masonry structures to BS EN 1996-1-1 & BS EN 1996-2. Contains recommendations on selection, density, positioning & embedment of wall ties

Approved document E: Resistance to the passage of sound. Part of the Building Regulations specifying the performance requirements of ties used in separating and external walls.

Generally, ties are placed in a 450mm vertical, 900mm horizontal staggered spacing pattern. Closer centres are sometimes adopted for larger cavity or heavily loaded walls where the declared resistance of the tie is compared to the lateral load to determine the tie density (Eurocode 6).

Around unbonded openings, ties should be placed not more than 300mm vertically apart and within 225mm of the opening.

50mm mortar embedding is about right isn’t it?

That’s the British Standard recommendation, but we would recommend allowing for 63-75mm embedment when determining the tie length required. This makes allowance for site variation and offers a reasonable working tolerance.

In the past, galvanised wall ties have been shown to corrode badly within cavity walls. Therefore, all our cavity wall ties are manufactured from grade 304 stainless steel as standard, ensuring full corrosion resistance for the duration of the building design life.

Grade 316 stainless steel wall ties are also available for ties used in heavy industrial or marine environments.

The new basalt fibre composite NEUTRAS wall tie is an extremely versatile product and has been designed to serve as a uniquely adaptable substitute for traditional steel ties. Wall ties crossing a cavity act as a thermal bridge and it is becoming increasingly important to reduce this transmission in order to comply with Building Regulations. Our NEUTRAS range of low thermal conductivity wall ties have high structural performance levels. They can be excluded from the current U value calculations in EN ISO 6946 and provide a credible solution to new legislation requirements.

Building heights, intended usage, structural formats, exposure to wind, height above sea level, cavity size, different brick and block types, insulation – all these factors and more can influence the specification of wall ties.

In other words, things can get complicated. So the easy answer to that question which wall tie should I use? is to get in touch with your BPC Fixings supplier or to email BPC Fixings directly via technical@bpcfixings.com

BPC Building Products Ltd.

Flanshaw Way

Wakefield

WF2 9LP

© BPC – 2023

Part of the Vista Group